HistoryMP18 is considered to be the first submachine gun practically used in that role. It was introduced in 1918 and saw use by German Army during WWI, and until 1920 by Police. Even though production didn't last long, MP18 became base for most SMGs designed as late as 1960s.

Design was done by Theodor Bergmann, Hugo and Louis Schmeisser. SMG is oficially marked MP18/I. Due to Army demand, initially MP18 used Luger Artillery drum mag inserted into a slanted magazine well. Later existing guns were modified back to original stick magazine.

There were actually several versions of stick magazine, with 32 (original), 20, 30 and 50 rounds (these were made post-WWII). A select-fire variant, MP28/II, was also introduced. Other variants and evolutions of this weapon were introduced by China, Spain, Austria, Finland. Also Japan introduced "Type 100", based on MP28 design.

More information can be found here:

http://en.wikipedia.org/wiki/MP_18http://world.guns.ru/smg/smg76-e.htmModelgunThis gun is not very popular among replica-makers, be it airsoft, modelguns, Denix, blank-firers. So far the only company to succesfully make a replica is Japanese CAW (Craft Apple Works), who have released a few variants in very limited numbers. I think that all these were manufactured by CAW together with Tanaka Works - confirmation would be welcome! I also found a single mention that Rokken has released an MP18 in the past, but without any details. There is another mention of a limited 6-piece production of MP18 replica, but I don't have any other details on that.

Modelgun MP18 variants that I know about are:

- MP18 w/stick mag, dummy version. It can cycle dummy cartridges. This version was announced in early 2002.

- MP18 w/stick mag, "special version". It is stamped "Theodor Bergmann Abt Waffenbau Suh" and has "S" letter next to safety hole. It was announced in 2002, too.

- Type 100 w/curved mag, dummy version. There are several variants with different stocks, I am not sure if there are other differences. This version was announced in late 2007

It is not clear how many pieces of each MP18 version were made. Number quoted for MP18 is just 200 pieces. It seems that initial 50 were dummy versions. I do not know if "special version" = cap firing, or if there were two cap-firing versions: one normal, one special.

There are very few parts available for CAW MP18. You can get spare magazine and cartridges (dummy and cap-firing). As far as I know modelguns and spare parts are all sold out from CAW, and there is no plan for another production run, so you would need to track them second-hand. Parts diagram included with modelgun also says that "Because of the limited production of the product, can not supply parts only."

Apart from original CAW parts I know one after-market company that made (makes?) steel trigger and sear replacement, called "Egypt". They are manufacturer of various custom parts, mainly for Colt 1911.

http://www.geocities.jp/egypt1911a1/CAW MP18 homepage:

http://www.caw.co.jp/caw/mp18/point.htmlCAW Type 100 homepage:

http://www.caw.co.jp/caw/type100/type100-3.htmlInteresting page about German WWII modelguns, more CAW MP18 pictures and mention of Rokken:

http://homepage3.nifty.com/nkoinuma/WW2G.htmTranslating information from that page would definitely help :-)

An earlier review of MP18 by Garyforce is available in this thread:

https://mp40modelguns.forumotion.net/modelgun-reviews-f4/caw-s-bergmann-mp18-sub-machine-gun-t229.htmModel that I have is MP18 dummy version that was found and converted by Francky to fire standard 9mm Luger cartridges with 7mm caps.

BoxCAW MP18 is packaged very similar to Shoei products (and recently also Hudson), in a plain, cardboard, stapled box. It has a white piece of paper with "MP18 Bergmann" text on top, and another paper with CAW logo and warning messages (in Japanese) on a side. Box separates in top and bottom parts. Bottom has styrofoam inserts that hold modelgun in correct position and protect it against bumps. Of course for transport everything would be wrapped in plenty of bubble-sheets.

Inside you will find modelgun, magazine and several pieces of paper: large white with parts diagram, large green that has the same parts diagram on half (scaled down), and cartridge instructions on the other half, shiny white product registration card (I think) and another white paper with text. Everything is written in Japanese.

Both modelgun and magazine are individually wrapped in thin foil. You might also find cartridges here, I believe that CAW included 5 or 10 cartridges (dummy or cap-firing depending on version).

Depending on strength of your will, it is at the latest after unwrapping bubbles when you go "WOW!" ;-)

Modelgun

ModelgunI just don't know how to start describing it.

There is one phrase that pops to mind and it is "Japanese precision". This modelgun is extremely well made, quality is comparable to Shoei models. Everything is detailed, well cut, rounded, finished, painted... as an example: all screws are done with such a precision, that you can unscrew/screw them delicately, with a very light force.

(nb: much later I discovered an interesting flaw, described in "Problems" section).

Model is HEAVY. Weight is over 3.5kg, same as the original. It sports a solid, wooden stock, something I find very attractive in a gun. The next thing that stands out is collar with a magazine well - solid, large, open to the left. It seems to be made of steel. Further to the front there is a barrel (steel again, as far as I can say), hidden inside a perforated shroud (steel again) that gives MP18 it's distinctive appearance. On the right side of the receiver you will quickly notice metal charging handle poking out. Once you unwrap and insert the magazine, it takes quite some time before you are able to put the model down

Heavy, very solid, it fits well in your hands. There is enough place for a comfortable grip with both hands and it is easy to find a good grip, unlike in STEN or even MP40.

Included instructions do not help a lot. It is actually a single sheet of paper with all parts roughly drawn on it. There is no numbers, names or explanation how to put it all together (or take apart). Once you have disassembled this model, it becomes clear, but at that point it is too late to use instructions ;-)

I have re-drawn the diagram and added descriptions (please correct if my naming is wrong). Numbers on diagram are not final yet, I still try to optimize it so that consecutive numbers belong to parts that go together. Currently the numbers are only based on drawing.

Click on miniature below to see full size.

Wooden stock is probably the largest single part in this model. Wood is of good quality, with a nice finish to it. Stock has a metal butt plate at the end, held by two large screws. Underneath the stock there is a sling attachment loop, also held by two screws. Trigger and trigger guard stick out from the bottom, positioned under the back end of the receiver. Guess what, it is held by two screws ;-) Front of the stock has a large metal hinge that holds together receiver and stock. Part attached to the stock is constructed from two metal pieces (inside and at the bottom of stock), held together with a large screw, forming sort of a bracket over the wood. It mates to the receiver portion using a large screw that stays in place, but is very easy to unscrew.

Sides of the stock, along the receiver, are slightly recessed to allow for better grip. At the top of the stock, near back end of the receiver, there is a metal bracket kept by three screws. This bracket holds receiver and keeps it from swinging on the hinge.

(nb: pictures taken with receiver removed for clarity)

Receiver sits on top of the stock, attached to it via hinge (near front) and a latch (at the end). Spring-loaded metal latch at the end of receiver will mate with the metal bracket on the stock to lock it in place. You can push that part towards receiver to slide it from under bracket, and then swing whole receiver up.

(nb: hinge picture is with barrel removed)

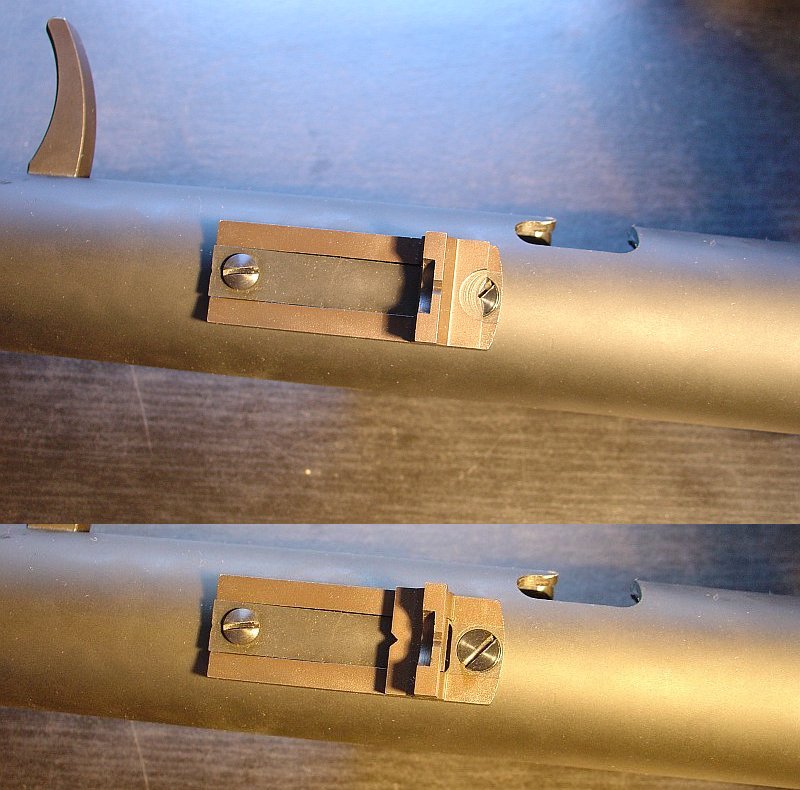

In the middle of the receiver, at the top, you will find a simple flip sight set for two distances. (note: MP28 had tangent sights)

Right side of the receiver has a hole through which bolt handle travels back and forth. There is also a notch that is used as safety - you can move handle into the notch, and it will not go forward when the trigger is pressed.

In front of the stock you will find a large metal collar that forms magazine well. Magazine well has a push-button type magazine catch, very easy to use. The right side of the collar has a hole for ejecting cartridges. Through the hole you can see an ejector. Collar is marked "MP 18.I", which is original gun number, and also "System Schmeisser" that refers to Schmeisser patent on this collar. MP40 uses same collar mechanism (but with magazine well pointing down) and it is due to using of that patent that Schmeisser name is connected with MP40.

The next part in front of collar is barrel shroud. It is perforated to allow for barrel cooling. It has a sling attachment loop screwed underneath, and front sight at the top near the front. "Business end" of the model is very interesting, because except for the barrel in the middle, space between barrel and shroud is filled with a disk with holes. This makes gun look consistently perforated, and I liked that detail a lot.

The only other marking found on the modelgun is a three-digit number - a serial number I believe. It is stamped in two places: at the bottom of receiver (near end cap), and on a side of the end cap. Modelgun that I have has two different numbers. I do not know meaning of this. It is possible that these should have been the same but someone made a mistake when putting model together (in factory or later). It is also possible that they are not supposed to be in sync.

Magazine

MagazineMagazine used by this modelgun is a stick-type magazine that appears in MP28/II and modified MP18/I. This variant is much more reliable than Luger Artillery drum magazines, so I can fully understand why CAW choose to replicate it. Still, it would be interesting to see MP18/I with angled magazine well, using Luger drum mags =)

I have not checked actual magazine capacity, but according to CAW it is 40 rounds. It is likely that when full magazine is loaded, there might be feeding problems. There was also a shorter 20-round version that you could buy as an additional accessory.

Cartridges

CartridgesOriginally cap-firing CAW MP18 was designed to fire MGC specifications 9 mm Luger CP-HW cartridges, but it should work on KSC or Mulberry Fields ones. Francky modification described here should work with standard 9mm blowback cartridge, Mulbery Fields being the best thanks to its shape. Garyforce in his review mentioned that both MGC and KSC 9mm work fine. I have KSC 9mm and Mulberry Fields 9mm carts, but so far only checked KSC ones. Obviously these cartridges use a single 7mm cap. They are loaded using the usual procedure.

https://mp40modelguns.forumotion.net/beginner-s-guides-tocartridges-f15/(cartridge pictures to be inserted here)FiringAs with all larger modelguns, firing it can be a mixed experience.

First of all you need to make up your mind whether you actually want to fire it. If so, first make sure you know how to clean (and partially disassemble) modelgun to avoid costly damage from cap powder residue.

Load cartridges with caps, then cartridges in magazine.

Pull back bolt, put it in safe position, insert magazine.

Release bolt handle from safe position, point modelgun in safe direction, point ejection port in safe direction ;-)

Wait, wait, wait... savour the moment ;-)

Pull the trigger and empty as many cartridges as you have loaded in one go - this model is auto only.

Depending on when you release the trigger, bolt might or might not lock in the rear position.

It will not lock when magazine is empty, it should lock if you interrupt shooting.

After shooting lock bolt in safe position, remove magazine, inspect chamber, proceed to cleaning.

You should be a happy person now :-)

At least in theory, because in practice this model, just like any other, has its problems and peculiarities.

(one day I will make a video ;-) )ProblemsJust like with any model, there is a lot of things that might go wrong.

The first problem is feeding.

Magazine that I have has A LOT of play inside magazine well. Mag bottom tilts almost 1cm! Unless it is pushed forward, it cartridges do not feed correctly. When it happens usually head of the cartridge will not find its way into the chamber, but will block between bolt and chamber.

If MP18 jams in that way, it is enough to pull back bolt into safe position, and shake out the cartridge. Unfortunately, due to weight of the bolt, force of its impact, and fact that model is made of metal, cartridge will get mangled. All cartridges that jammed in my MP18 had a damaged rim and head, because cartridge was jammed diagonally, bolt face together with area around chamber "adjusted" it. Workaround is to keep magazine pushed forward, so cartridge head is closer to chamber when it is picked up by the bolt. Another might be modifying mag lips, but I don't have experience yet how to do that.

Side-effect of feeding problems that might go unnoticed initially is that extractor will bend when it hits a blocked cartridge. Instead of being straight it gets arc-shaped and might interfere with receiver when bolt moves. Also the edge of extractor claw gets slightly deformed.

Here you can see three cartridges: two have been fired through MP18, one is brand new. You can easily tell which ones are used, based on the head as well as the rim:

The second problem is related to open bolt.

When one of caps is too weak, the bolt will not move back far enough and will not lock on the sear when you release trigger. This means that replica will proceed to shoot another cartridge (or more). This is not a serious problem and it is typical for any open bolt SMG - modelgun and real.

There is no safety that holds bolt in front position, so if magazine is inserted with bolt forward and gun is bumped, bolt can travel against weak spring pressure, strip a cartridge from magazine and fire. Modelgun position to observe it is if you hold it with barrel pointing up, otherwise bolt weight helps a bit. Again, this is typical for open bolt SMG design, real and modelgun. Keep bolt locked in safety when magazine is inserted.

The third problem is wear to the receiver.

Whenever bolt travels back, it has enough force to go all way back. Side result is that handle also travels all way back, and hits end of its hole in the receiver. You can clearly see that this part has been hammered due to shooting. This is unavoidable due to receiver material (aluminum I think). That problem could be fixed by installing a buffer inside the receiver to stop the bolt from hitting the back of receiver, I think. The wear occurs also when you pull the handle to safety, because you would normally pull it against the back end, then rotate - at that point bolt and receiver touch and scratch.

The fourth problem is related to receiver design.

Receiver is made of soft metal (aluminum most likely), while the end cap is steel. Until you start complete disassembly (not recommended) it is not a problem, but during disassembly you have hard thread moving through soft thread. It is obvious that thread on the receiver gets damaged when you disassemble the model. It is made even more obvious due to heat generated by friction of threads during unscrewing of end cap, plenty of powder residue left in the threads after separating parts, and slightly deformed threads. This problem can be solved by using a specific technique for unscrewing the end cap (presented in disassembly instructions) and by careful cleaning, reshaping and oiling of the threads before you try to put everything back together.

Given that MP18 is not actually designed to be disassembled often, I no longer consider this a problem - once you are aware about it, it is solved. I guess that problem might be also cause by the fact that my end cap and receiver have different serial numbers, so maybe they are not matched correctly?

The fifth problem is specific to the MP18 that I have.

Metal bracket that holds end of the receiver has been installed slightly wrong at the factory. Front should be parallel to receiver end cap (or ortogonal to targeting line). Mine is at a very slight angle because one side is slightly shifted, about 1mm.

What it means?

Receiver still locks onto the stock, but the part that locks is forced to be at a slight angle due to bracket's angle. Now, that part is screwed on the end of bolt spring guide. Spring guide is now also at a slight angle instead of going exactly in the middle of receiver/bolt. Even a slight angle makes the front end of spring guide to not leave enough clearance between bolt and itself for the spring. Whenever bolt travels back, spring, spring guide and inside of the bolt get scratched.

You can hear sound of spring forced through the gap between guide and bolt. That also influences performance.

Click miniatures to see incorrect position of spring guide (called "plunger" in the drawing), guide touching spring in assembled replica, and a drawing explaining what happens.

There are two ways to solve that: the first one would be to move bracket into correct position. Issue with that is that with just 1mm difference in position, two screw holes would need to move 1mm - overlapping new and old hole. Enlarging existing hole is not a good solution (wobble), filling existing holes and drilling new ones might be a better way, but difficult to do precisely.

The second possibility is to get a new stock and transplant all parts (hinge bracket, trigger assembly, butt plate, sling loop). I have obtained a spare stock and I plan to modify it to accept CAW MP18. This wooden stock is a replica of an original, and it has a different layout - quite a few modifications will be required to put it all together. See pictures of this stock in another post below.

Basic disassembly for cleaningAfter shooting it is a good idea to clean your model as soon as possible.

For basic disassembly required for cleaning please see this thread:

https://mp40modelguns.forumotion.net/modelgun-stripping-and-rebuild-guides-f12/caw-mp18-basic-disassembly-for-cleaning-t2215.htmThere is also another thread explaining advanced disassembly, provided just for reference. Do NOT attempt this unless you absolutely must.

https://mp40modelguns.forumotion.net/modelgun-stripping-and-rebuild-guides-f12/caw-mp18-advanced-receiver-disassembly-t2216.htmOverallMP18 is a very rare modelgun that one would spend a lot of time (and money) to get. It is a VERY nice replica of high quality, made with attention to details, with real wooden stock and every other part metal. Even with slight problems described above it is a very satisfying and astonishing model! Keep in mind that MP18 is THE most expensive modelgun that I know, surpassing even Shoei! :-/

I do not plan on firing MP18 a lot, maybe a session to make video for the forum :-)

(edits: added Rokken information, corrected production info, modified cartridge description, other minor word corrections || added picture to show receiver latch problem || replaced parts diagram with new version, added cartridge pictures, added more pictures as thumbnails || updated info on aftermarket parts || added magazine pictures, small corrections)PS: if you post photos in this thread, please keep width under 800px. Larger pictures ruin text layout on smaller monitors