Post by Mark Man, that's bad news claymore!

As I don't have a clue just why the MGC .45 barrels break as often as they have for you, I have decided to take my available MGC .45's apart to see what possible areas that I can spot as weak. Also, I will see if there is any thing that can be done about the barrel(s) to see if there is a "fix" that can be put in place to prevent the barrel from having a premature and early death. As I have not had any barrels break on me (yet, as I rarely shoot any of the MGC .45's in my collection.

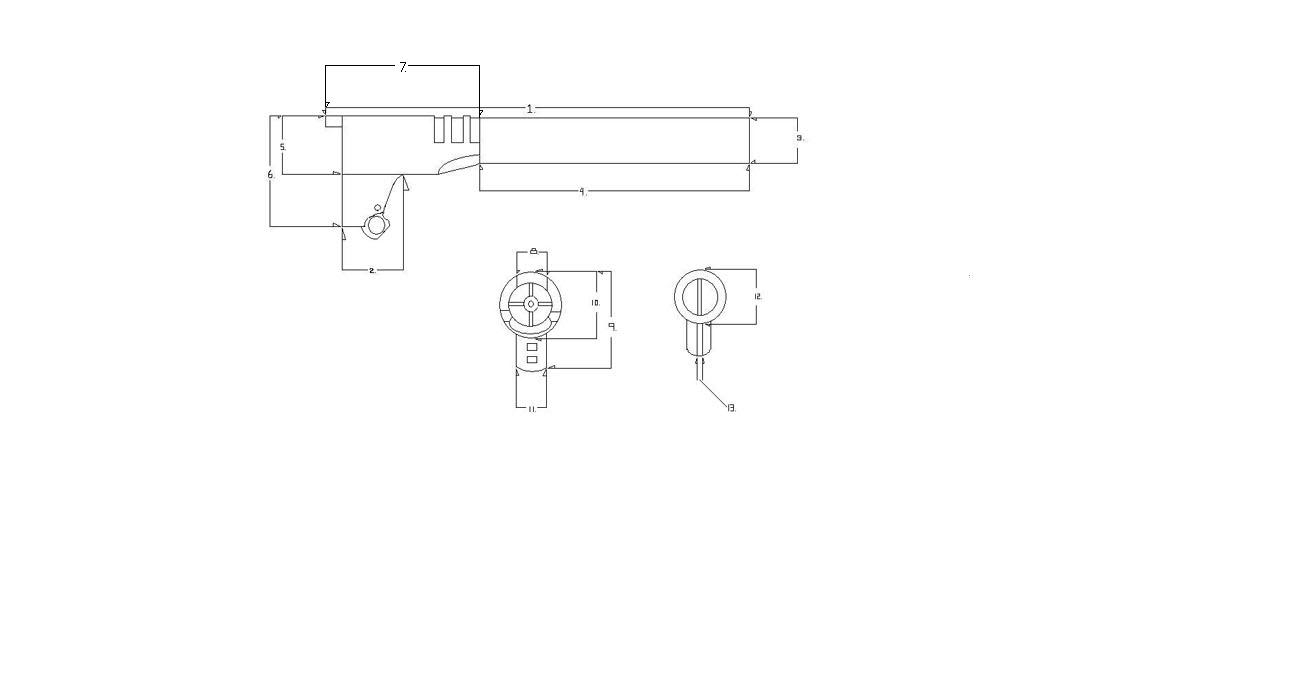

Looking at my available MGC .45 barrels, I will note their differences as well as their visible weak points and any possible fixes. This is an illustration that I have drawn-up to illustrate the key dimensions of the MGC .45 barrels that I have in my possession. This by all means is not a complete list of the different MGC .45 barrels if you have any dimensions to add please let me know. This might be a little large for many monitors and might be bad on dial-up sorry...

A general over-view of the MGC .45 barrel shows that there are many variants of the .45 barrel that MGC has made over the years from the earliest all metal to the latest HW versions. The all plastic barrels are our focus here as they are certainly the most common today. The barrels are usually molded out of ABS resin some are "chrome" plated while the vast majority are black.

The barrels commonly have a black satin finish that is molded in the parting line is located on the side of the barrel and it doesn't look to be a weak point in their construction. The molding is clean with out "flash" and the color as well as the plastics consistency is good. The ABS resin used in the barrels molding seems to be fairly hard when scratched with a sharp knife indicating that it is possibly brittle when excessive shock is applied. NOT GOOD.

The feed ramp that is molded into the barrel is thin at the chambers bottom sides and this I think just might be a big problem for longevity of the barrels in the MGC .45 especially the later "real size".45's that probably have really thin barrels in that area. As I don't have a "real size" .45 at this time, I cannot tell if their barrels are weak at that point. The barrels are fairly thick at their sides whether that is mostly due to the fact that these use the earlier CP cartridges that are smaller in diameter and so they have thicker walls I don't know..

The detonator is held in place with a small set-screw at the barrels bottom as well as internal "ribs" to center the detonator in the chamber. As this set-screw is carbon steel it can rust and swell eventually splitting the barrels bottom if the set-screw is left in place and allowed to rust after the barrel is clean..The detonator is made out of stainless steel and it has a groove that the set-screw goes into. Too much strain on this screw due to being overly tight can cause problems as well as strip out the threads in the barrel.

The plastic lower part of the barrel just below the chamber is for a rotating barrel link that is supposed to lower the barrel in the real gun during recoil. MGC (as well as Marushin) probably thought that they needed to include this feature for realism. Otherwise, this feature is not needed as the locking-lugs on the barrel never come close to the recesses in the slides underside. This rotating link is made out of thin stamped blued steel and it pivots on a solid steel pin. The link is hardened and it rotates freely in it's travel it's front end has a flat area that the recoil spring guide fits against. This area that the link is attached to is fairy thick and it looks strong.

The barrels fit in the slide is best described as "loose" at best and I doubt that it's loose fit will cause any undue stress to the barrel.

The MGC "Bowling Pin" version's bull barrel:

Actually, this isn't really a "bull barrel" its really a 6.25" long government model barrel with a sleeve/compensator that slips over the barrel and it is retained with a set screw.

This is a so called "black" barrel and it is set up for the earlier small CP .45 cartridges not the late model real size type. I did notice some possible damage on the bottom of barrel below the chamber area just above the barrel pivot! It looks like two deep cuts (dents?)This indicates to me that the barrel is or was being slammed against the sharp edges on the frame next to the feed ramp. These edges should be filed smooth as they are fairly sharp to the touch. To me, it looks as if the barrel was being slammed into the frame when it was being fired due to some bind in the action or something? (again, I really haven't fired this MGC very much)

The barrel has "BARSTO 45 ACP" on its chamber top.

It's dimensions are as per above illustration:

1. 6.25" long

2. .910"

3. .579"

4. 4.340"

5. .671"

6. 1.209"

7. 2.446"

8. .414"

9. 1.150"

10. .663"

11. .381"

12. .679"

13. .90"

The Colt Combat Commander (series 70) barrel(s) as I have two of these, I measured them and their barrel dimensions are on the "dot"

These are still the earlier small CP .45 cartridge barrels and they are both black in color. As I have only fired one and rarely at that, I detected no damage as well as no wear that was apparent at least to me.

Their dimensions are:

1. 4.274"

2. .840"

3. .579"

4. 2.241"

5. .683"

6. .685"

7. 1.210"

8. .415"

9. 1.083"

10. .668"

11. .376"

12. .578"

13. .090"

I will try to get more information on the other MGC .45's that I have in my collection and post them tomorrow as it's getting late here.

_________________

Wanted to buy: MGC Sten MK3....trades?(still)

MGC MP40 Marushin MP40 Nakata MP40 TRC MP40

Modelgun manufacturers, past and present:CMC,CAW,Hudson,HWS,LS,MGC(R.I.P. 1960's~2007) Marushin,Marui,Kokusai,Shoei,Tanaka and Western Arms