A few years ago a guy that I worked with asked me to look a what he thought was a real mp40. He wanted to know what it would take to make it fire again. While looking at it I noticed there was no waffenamt markings. It also had a solid barrel. I told him that it wasn't a real mp40 and take a lot of time and money to make it into a closed bolt semi auto. He told me I could have it for $50. I saw the mgc68 marking and looked it up. Then I found this website and learned about plug fire guns. It was missing the detonator and had no cartridges or caps. I decided that it was kind of expensive for a toy and decided not to buy any.

After looking at the mgc68 and others semi auto mp40 builds I came up with a idea for my own build.

Afterwards I kind of wanted a full auto plug fire. Searched on ebay and gunbroker for a few years. Nice looking ones went for $1000 to $2000. Heavily rusted and beat up ones were still over $500. They didn't have cartridges, mention if it had the detonator, or if it was a solid or open barrel. Recently got a notification from ebay that there was a new listing. It was listed as fair condition, but the pictures didn't look bad. It said the bolt and other parts were missing. I bought if for $275 only a few minutes after it was posted.

ebay posting pictures

I still had the barrel, resting bar, barrel nut, barrel washers, sling loop, trunnion, trunnion screws, bolt, bolt spring, sear, trigger, and trigger linkage left over from the first mgc68. The first mag was sold a while ago. Figured I should have all the parts needed to fix this new mgc68. When it came in it was missing the bolt, bolt spring, trunnion screws, bottom grip frame screw, and both fore grip screw spacers. The barrel is a open barrel. The first mgc68 had a roll pin in the bottom of the barrel nut that needed to be removed to remove the barrel, but this one doesn't have a pin. It is missing the detonator. When I looked here years ago there was a drawing for the detonator, but I can't find it now. I have a lathe so I can make one if someone could give some measurements.

During disassembly the stock came apart. It is a steel tube with zinc pieces pressed in on each end. Put it back together but it was a loose fit. Took some supper alloy 1 from muggyweld and soldered everything back together. Then filed and sanded until the two blended together. Cleaned up the parting lines while I was at it. It looked like it was all one piece, but after bluing there is a slight color difference between the steel and zinc.

The mgc68 was painted. Even with it painted it did look beautiful, but with some of the paint scratched off and having so much steel it needed it needed to be blued. Used goof off to remove the paint. Once the paint was off the outside was bare metal. The inside was still blued. Who ever painted it removed the bluing and polished up the outside. There was almost no rust and it was just surface rust, not pitted like many of the others for sale. All the seam lines except the stock and trigger area were cleaned up before it was painted. The japan lettering on the bottom of the grip frame was also removed and smoothed out. There were some filing and sanding marks left over from the previous restoration. I cleaned up the remaining parting lines and gave the other parts a slight sanding. It is a reproduction of a wartime manufactured weapon, to a highly finished show piece.

Heated the parts for a few seconds with a propane torch. Then whipped the parts with a paper towel soaked in BROWNELLS OXPHO-BLUE. Kept the part wet for a minute then let it air dry while working on the next one. Repeated that on all the parts until they didn't get any darker. Most of the time it was 3 or 4 times. Then took a rag and dipped it in some used motor oil and covered the part. Wiped off the parts with a clean rag until the extra oil was off. The used motor oil really made the parts darken up. The zinc and steel parts also blend together better.

The fore grip is black but the pistol grips are brown. Thought they were supposed to be one or the other color but match each other.

For the semi auto build I used mags from a Belgian vigneron. They were copied off of the mp40, but are not compatible. Since the mgc68 has slightly different dimension than a real mp40 they can be made to work. The back of the mag needs to be filed down slightly. The mag locks in place too low. The upper part of the mag catch needs to be cut out. The bottom needs to be raised up and filled with some weld. That brought the mag to the right feeding height but the mag can still be pushed up too far. Added some weld to the bottom stop and filed down until it locked in place. That let 9mm feed perfectly into the semi build. Need to get some pfc cartridges to see if it will feed or if other changes need to be made.

vigneron top mgc68 bottom

vigneron left mgc68 right

mgc68 top vigneron bottom

Both mags would fit in and lock in place, but could move and drop out. The mag catch would then not move. The sheet metal around the rear of the mag catch was bowed out and the mag catch would slide toward the back and jam. The mag catch is not supposed to go deeper than the sheet metal. Took a hammer and chisel and worked the sheet metal back to where it is supposed to be. After that and some oil the mag didn't drop out. It still can move around a little, but mp40's have that problem.

Use the part named the fore grip as the forward grip and don't grab it by the mag as they do in the movies and a lot of problems can go away. The mp40 should have been designed with a proper fore grip. Many times I grab the mag too because that's where the fore grip should be.

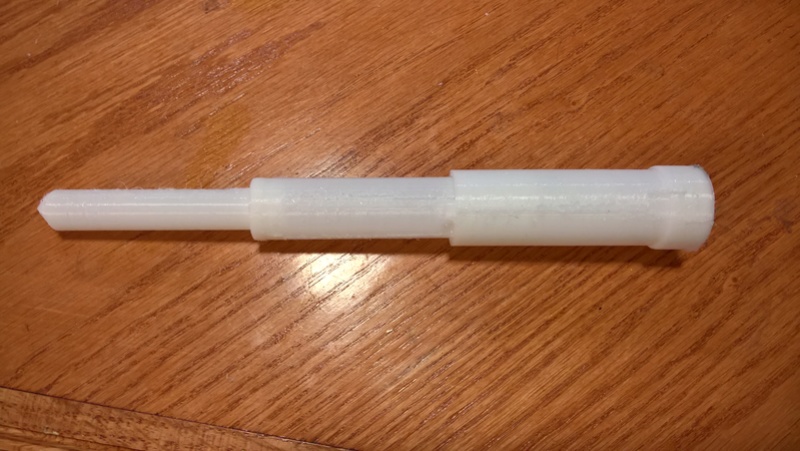

The fore grip screw spacer are steel cylinders that are slightly beveled for the screw heads. Didn't have the time to try making some on the lathe. I guessed at the measurements and made a 3d model and 3d printed some. They turned out pretty close. Then I realized I could have just measured the ones from the first mgc68. Will make some steel ones when I get some time later.

The outside of the barrel looks like it is pitted from rust, but it is made out of zinc. The front sight base looks pretty good. Did they do that bad of a casting job for the hollow barrels? My solid barrel looks a lot better. To clean up the barrel would mean removing quite a bit of material.

Haven't decided yet what to do with the barrel. I could take the first barrel and make it into a show barrel by cleaning it up, milling the bottom and front sight base to fit a reproduction resting bar. I could turn this barrel down and fit a reproduction resting bar. Or say its original don't try to make it better.

Saw a post on ebay for a steel barrel nut. I've heard of having replacement steel bolts. Is there a problem with the zinc barrel nut or is it only to make it look better? I removed the paint and removed a little casting blemish from the nut, but didn't polish up the rest of it. It still looks cast instead of machined.

Now the only real problem I have with the mgc68 is the bolt spring. Found a 3d file for one and 3d printed it. Would need to find a narrower spring that is light enough for the bolt to work.