REFURBISHING A RMI (MGC) P-08 LUGER

THE LUGER AS IT ARRIVED - MAGAZINE & TRIGGER PARTS MISSING

THE LUGER AS IT ARRIVED - MAGAZINE & TRIGGER PARTS MISSING

This P08 was a “steal” on a local internet, auction. I knew that some parts were obviously missing, and bought as a winter project.

I contacted Richard Jones on this forum and he has most of what I need. And while waiting for the parts to arrive I got hold of a second RMI P08 with most parts intact.

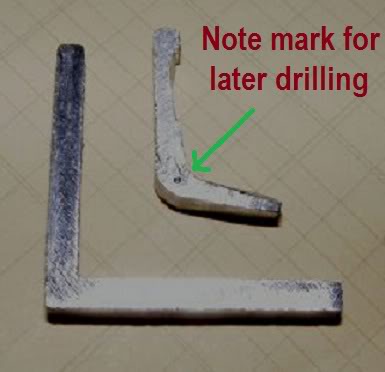

I knew the rectangular side plate from Richard was sending me did not include the “L” shaped trigger bar; and the L-bar on the borrowed Luger was likewise missing.

Using the cover-plate and photos from a REAL P08 as a guide I decided to fabricate one.

First, being naturally lazy, I made an L-bar from a piece of 2.5mm aluminium (aluminum to Americans) angle. Easier to work with, and quick to shape.

CUTTING AND FITTING

CUTTING AND FITTING

SHAPING AND TRIMMING TO FITOf course it was too soft and gave way near the hinge hole after several plays.

SHAPING AND TRIMMING TO FITOf course it was too soft and gave way near the hinge hole after several plays. But I got the basic dimensions right and it worked OK for a while. However the aluminium bar made a good template for the steel version (cut from a 4mm steel bracked in my junk box). The photos tell the story.

STEP1

STEP 2

STEP3

STEP 4

STEP 5

STEP 6

STEP 7

STEP 8

BUT WAIT! THERE'S MORE!

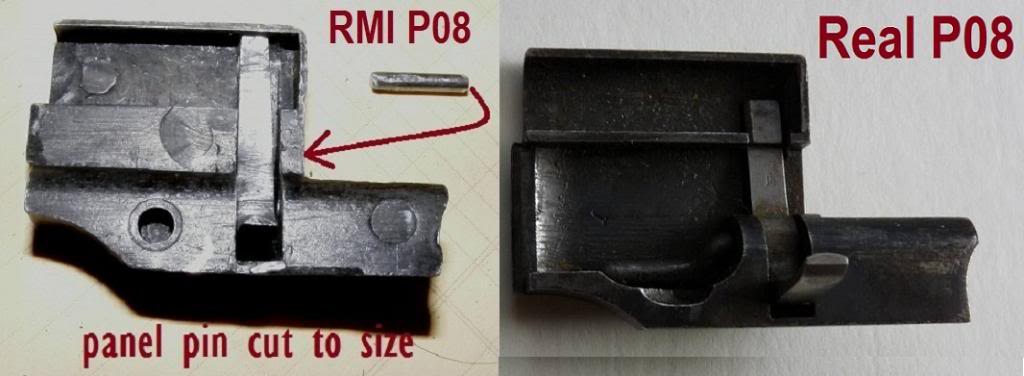

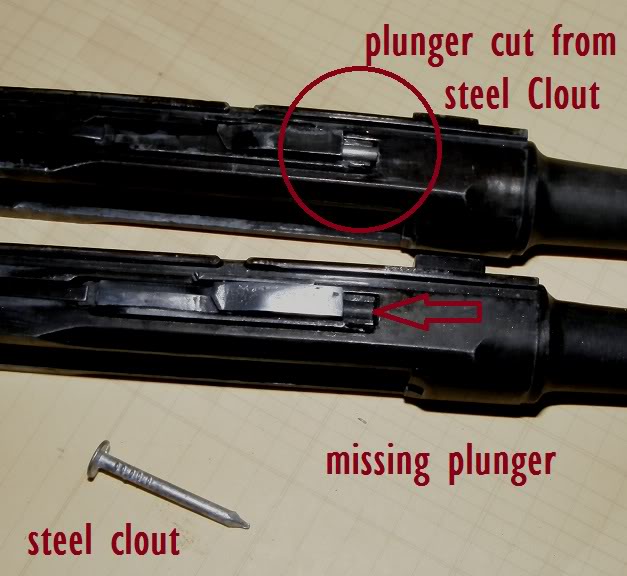

BUT WAIT! THERE'S MORE!But then I discovered more bits were missing, by comparing my WE P08 GBB BB pistol. The L-bar striker normally strikes a steel spring-loaded plunger on the actuator bar of the P08. These parts were missing on both my and my friend’s Luger.

I cut one each out of some galvanised steel clouts from my tool box. I have yet to make some springs, but by cutting the clouts longer than required, they sit adequately in to recessed hole and seem to work OK for now; I'll make some springs when I find some spring wire.....must be some here somewhere!

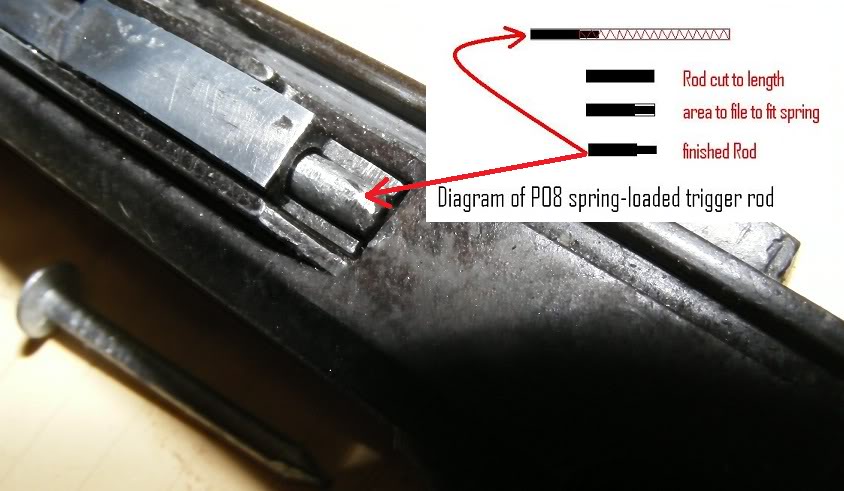

AND YET -----MORE! THE FIRING PIN/BARNext, the actual firing pin/bar (dummy version) in both our P08’s had warped over time.

I wonder if ANYONE has some ideas about how to straighten them. Made of zinc, it may be a difficult process – but I am open to ideas.

I wonder if ANYONE has some ideas about how to straighten them. Made of zinc, it may be a difficult process – but I am open to ideas. Richard has some straight ones (not yet here in NZ), but it might be good to have a spare anyway.

THE MISSING MAGAZINE PROBLEM SOLVES EASILY!

THE MISSING MAGAZINE PROBLEM SOLVES EASILY!Finally, the P08 had no magazine. I measured the dimensions and got hold of Francky.

After some discussion I ordered a Marushin P08 mag from him – and it didn’t take much to make it fit easily. Just a fraction of a mil filed off the Luger where the mag rib goes into it; and a fraction at the base of the pistol grip where the mag finger grips rest.

And it's perfect as the dummy rounds cycled just fine!

RMI P08's fall apart!My friend’s P08 will, like mine, work once the firing pin/bar is fixed – but a word of caution.

The MGC RMI Luger falls apart easily if the latching bar is not secured! Maybe due to time, or wear, it comes loose and drops out with relative ease, whereupon out drops and square cover-plate and associated bits and bobs. Not very useful in a theatrical or demonstration setting - unless you want a comedy show!

At the very least it’s been a great exercise in familiarity with the P08 and at best a load of fun trying to solve the various issues.

But like I said,

if we could straighten out the warped zinc - that would be a bonus.

THE FINAL PRODUCT!

(My mate's P08. Mine will be completed when the parts arrive!)